Sealed Quench Furnace

The multipurpose batch type chamber furnace plants or Sealed Quench Furnaces has revolutionized the heat treatment industry in the last few decades thanks to its versatility, easy integration in automatic treatment lines, providing flexibility of metallurgical processes, product mix and layout, with maximum quality heat treatment in terms of reliability, predictability and repetitiveness.

Description

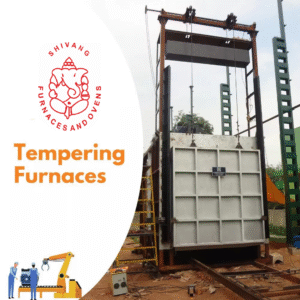

These plants are normally coupled with companion equipment like Preheating and Tempering Furnaces, Washing Machines, Stationary Table, Scissor Lifts and fully automated one or more Charge Transfer Cars- all designed for maximum reliability.

Features – Sealed Quench Furnace:

- Heating System can be electrically heated through radiant tube heaters type E or Gas Fired through high efficiency recuperative burner system type G.

- Gas used for heating and process can be LPG/Propane/Natural Gas supplied.

- Available in the versions of Straight Through or TWO DOOR (TYPE CBUT) furnaces with one or more chambers, and In-Out or SINGLE DOOR (TYPE CBUR) furnaces with frontal loading/unloading.

- Furnace atmosphere possible:

- With Endogas and LPG/Propane/Natural gas

- With Methanol and LPG/Propane/Natural gas

- With Methanol + Nitrogen and LPG/Propane/Natural gas

- With Direct Gassing Process by LPG/Propane/Natural gas and Air

- Gas Carburizing possible:

- With direct quenching

- With intermediate cooling

- With charge cooling under protective gas

- Oil Cooling possible by Air or Water.

- SCADA (Supervisory control and data acquisition system) to provide operational control, standard recipes and recipe management

- Fully Automatic and Man less installation operated from the control room

- Can also be equipped with Ferriitic-nitrocarburizing capabilities, so that it is possible to first do basic hardening in the conventional way followed by nitro-carburizing in the same furnace on the same batch

- Option available with oil or salt quenching.

Reviews

There are no reviews yet.