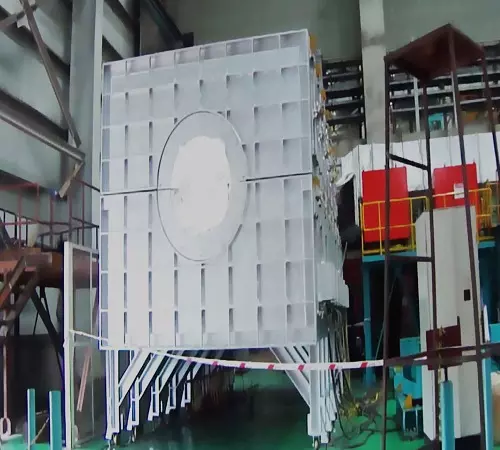

Post Weld Heat Treatment Furnace

SHIVANG FURNACES offers Post Weld Heat Treatment (PWHT) to retain the material strength of the part after welding. By PWHT, one can control the hardness of the material and reduce the residual stress induced during welding.

Hence, after welding, the material is processed through Post Weld Heat Treatment. PWHT helps to avoid weld failures, reduces susceptibility to brittle fracture, and minimizes high cracking potential.

Description

- Hydrogen removal

- Reduction of residual stresses

- Corrosion resistance

- Dimensional stability

- Tempering

- Enhanced ductile roughness

Post Weld Heat Treatment (PWHT) is carried out in Bogie Hearth Furnaces and Chamber Furnaces. The most common types of PWHT are Post Heating and Stress Relieving.

POST HEATING

Hydrogen-induced cracking is a common occurrence during welding, caused by high levels of hydrogen diffusing into the material. After welding, the material continues to permeate hydrogen from the welded area. This PWHT process should start immediately after welding and maintain a high temperature for a couple of hours. The exact temperature depends on the thickness and type of material used.

STRESS RELIEVING

Once the welding process is complete, the material contains a high level of residual stress, which can lead to stress corrosion and hydrogen-induced cracking. PWHT releases these stresses and reduces cracking. The temperature is set and adjusted as required based on the material and process parameters.

Factors for Applying PWHT Process

Material type and thickness

Welding method and joint configuration

Desired mechanical properties

Prevention of residual stress and cracking

Reviews

There are no reviews yet.