Electric Oven

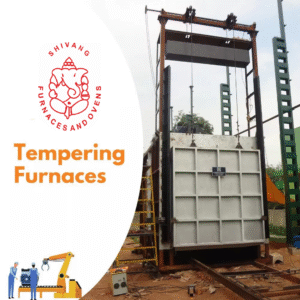

SHIVANG FURNACES has built a large number of electrically heated and fuel-fired Bogie, Fixed, and Continuous ovens over the past two decades.

SHIVANG FURNACES offers a full range of Bogie, Fixed, and Continuous ovens up to a capacity of 500 MT, catering to foundry cast houses, heavy engineering, automobile, rail wagon, electrical machines, and other metal industries, with a temperature range of 500°C to 4500°C.

The fixed and bogie hearth ovens can be provided with single or double doors, while continuous ovens are always supplied with double doors for front-end charging and rear-end discharging.

Materials are loaded onto bogie hearth ovens using an EOT crane or other mechanical devices on the electro-mechanically operated bogie, and onto fixed hearth ovens using a charging machine or air casters, to achieve the desired drying and curing.

Description

The continuous ovens from SHIVANG FURNACES can be conveyorised or trolley type. In conveyorised ovens, the conveyor is electro-mechanically operated, while in trolley-type ovens, the pusher can be either electro-mechanically or hydraulically operated. Material is loaded at the front end of the conveyor or trolley and unloaded at the back end of the oven after maintaining the desired retention time for satisfactory drying or curing.

Electrically heated ovens feature a resistive cartridge-type or tubular-type heating system located along the side, back walls, or roof of the oven. The heating elements are divided into suitable zones based on oven size and are controlled via a PID-based control philosophy with thyristor/contactor relay logic.

Fuel-fired ovens are equipped with high-efficiency burners, supported by a full combustion system with safety arrangements.

SHIVANG FURNACES Bogie, Fixed, and Continuous ovens are generally lined with mineral wool or ceramic fiber blankets packed between double-wall panels on the side walls, roof, and door, while the hearth is designed to minimize skin temperature. The inner walls can be made of mild steel or stainless steel, depending on the service temperature.

The ovens are provided with suitable baffles and recirculation fans to ensure better heat transfer through convection and good temperature uniformity. The baffles and recirculation fans can be made of mild steel or stainless steel, depending on the service temperature. The recirculation fan drive motor is VFD-driven for soft starting and better temperature control.

Reviews

There are no reviews yet.