High Temperature Furnace

SHIVANG FURNACES is recognized as a successful name in High Temperature Furnaces. We use Silicon Carbide (SiC) Heating Elements for these high-temperature furnaces. These furnaces can be used for producing technical ceramics and for sintering operations at a working temperature of about 1550°C.

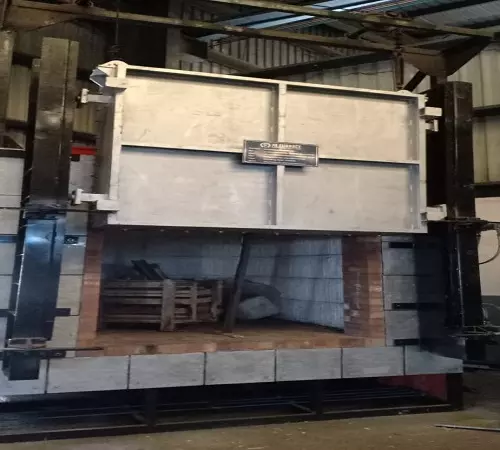

The High Temperature Furnace is equipped with high-quality insulation fiber blocks. The furnace has a multilayered lightweight refractory brick on the heating chamber side. The SiC heating rods are vertically installed in the furnace to provide uniform heating. The SiC rods are controlled by a thyristor controller, which counteracts the aging process of the heating elements

Description

- The maximum operating temperature is 1700° C.

- Heating is provided from both the sides through vertically mounted SiC rods.

- The SiC rods are controlled by a thyristor controller which counteracts the aging process of the heating elements.

- The swing door is provided with a hinge.

- Multi-layered insulation for better performance.

- For better ventilation, Dual shell housing is provided.

- Lined with lightweight refractory bricks.

- Motor-Driven exhaust provided on the furnace roof along with exhaust gas piping.

- These High-Temperature Furnaces are completely automated and run on SCADA systems with PLC’s to control the entire system along with documentation and monitoring.

- High-temperature accuracies with long heater life and refractory life are a feature of these Furnaces.

- Advanced safety concepts.

Reviews

There are no reviews yet.